Antioxidant

Other Auxiliary Agent

Petroleum Additives

Adsorbent

Water Treatment Chemicals

Rubber Additives

Adhesive Additives

Cross-Linking Agent

Flame Retardants

UV Absorbers

Organic Extractant

Resin Additives

Electronics Chemicals

Pesticide Additives

Building Chemicals

Plastic Additives

Oilfield Chemicals

Adhesive

Plastic Rubber Chemicals

Paper Additives

Molecular Sieve

Coating Additives

Textile Auxiliaries

Fluorescent Brightener

Polyethylene Glycol Derivatives

Coupling

Forest Chemicals

Leather Auxiliary Agents

Beneficiation Agents and Smelting Additives

Dye Auxiliaries

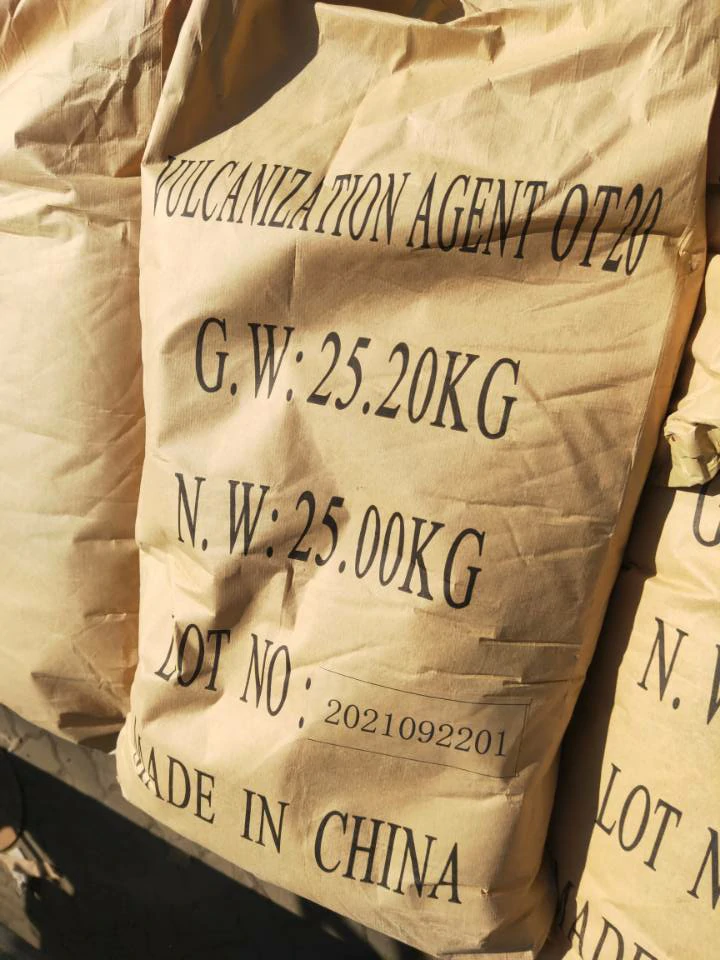

CAS:9035-99-8

Molecular Formula:S

Alias

More Information

Polymeric Sulfur; Polymer Sulfur; Bensulfoid; Asulfa-Supra; Bostex 410; Agri-Sul; AN-Sulfur Colloid Kit; Aquilite; Atomic Sulfur; Rubbervulcanizationagentis(Ot); Sulfur, Homopolymer; Insoluble Sulfur IS-60; Insoluble Sulfur HS OT-20; Insoluble Sulfur HD OT-20; Insoluble Sulfur 6005; Insoluble Sulfur IS60-10; Insoluble Sulfur IS HS 70-20; Insoluble Sulfur IS60-33; Insoluble Sulfur OT-20; Insoluble Sulfur OT-33; Insoluble Sulfur IS90; Insolble Sulfur

Brief Introduction

1. the most important application is as accelerator and cross-linking agent in rubber industry;

2. in the tire industry, a large number of accelerators and cross-linking agents are required, which are indispensable and important additives. Integrating practicality and appearance requirements, is is is widely used in some products bonded by rubber and structure, such as white tire side glue, tire turnover, buffer rubber, rubber hose, carcass rubber and adhesive tape. While "not spraying frost", it ensures the appearance of semi-finished rubber products.

3. The application market of is products is very wide, and is can be found in rubber products such as cable shell, waterproof hose, oil sealing material, raw tape, automobile inner tube, insulation protection products, automobile interior parts, etc.

4. in addition to industrial application, it is also widely distributed in daily necessities. Common light colored rubber products in the market often require a large amount of sulfur, such as rubber shoes with good waterproof performance, seals commonly used in hydropower construction and other special rubber products, as well as household rubber products, toys, latex gloves and other high-grade rubber products. Is can improve the adhesive ability between rubber layers, greatly improve the quality of common rubber products and prolong the service life. It has many unique advantages over ordinary sulfur.

CNY 10 Million

173160m²

100-500 People

Manufacturer

Manufacturing

| Product Photo | Specification | Grade | Max Capacity | Certificates | Package | |

|---|---|---|---|---|---|---|

|

|

||||||

| Tech Grade | 10000 tons/year |

25kg /

Woven Bag

25kg /

Paper Bag

|

||||

| Tech Grade | 10000 tons/year |

25kg /

Woven Bag

25kg /

Paper Bag

|

||||

| Tech Grade | 10000 tons/year |

25kg /

Woven Bag

25kg /

Paper Bag

|

||||

| Tech Grade | 10000 tons/year |

25kg /

Woven Bag

25kg /

Paper Bag

|

||||

| Tech Grade | 10000 tons/year |

25kg /

Woven Bag

25kg /

Paper Bag

|

||||

| Tech Grade | 10000 tons/year |

25kg /

Woven Bag

25kg /

Paper Bag

|

||||

| Tech Grade | 10000 tons/year |

25kg /

Woven Bag

25kg /

Paper Bag

|

||||

| Tech Grade | 10000 tons/year |

25kg /

Woven Bag

25kg /

Paper Bag

|

||||

| Tech Grade | 10000 tons/year |

25kg /

Woven Bag

25kg /

Paper Bag

|

Main products:

Insoluble Sulfur

/2-Mercaptobenzothiazole

/2,2,4-Trimethyl-1,2-Dihydroquinoline

/N-Phenyl-2-Naphthylamine

/N-Isopropyl-N'-Phenyl-P-Phenylenediamine

/Rubber Antioxidant 6PPD

/2,2'-Dithiobisbenzothiazole

/N-Cyclohexyl-2-Benzothiazolesulfenamide

/4-(Benzo[D]Thiazol-2-Ylthio)Morpholine

/N-Tert-Butyl-2-Benzothiazolesulfenamide

/Thiram

/1,3-Diphenylguanidine

/4,4'-Dithiodimorpholine

/Cyclohexylthiophthalimide

CAS:97-74-5

Molecular Formula:C6H12N2S3

Alias

More Information

Bis(Dimethylthiocarb; Bis(Dimethylthiocarbamyl) Sulfide; TMTM; TS; Rubber Acceleratortmtm; Rubber Accelerator Tmtm - 80; Thiodicarbonic Diamide([(H2N)C(S)]2S), N,N,N',N'-Tetramethyl-; 1,1’-Thiobis(N,N-Dimethylthio-Formamid; Tetramethylthiuramammonosulphide; Tetramethylthiuramammoniumsulphide; Tetramethylthiurammonosulphite

Brief Introduction

Rubber vulcanization accelerator tetramethyl thiuram (TMTM) is a green and environmental friendly rubber vulcanization accelerator. It can not only be used as a vulcanizing agent, but also as an effective activator of thiazole and hyposulfonamide accelerators. It has the function of a secondary accelerator, making the dispersion of thiazole and hyposulfonamide more good and the product transparent.

CNY 60 Million

106560m²

100-500 People

Manufacturing

Manufacturing

| Product Photo | Specification | Grade | Max Capacity | Certificates | Package | |

|---|---|---|---|---|---|---|

|

|

||||||

| Tech Grade | - |

|

25kg /

Paper Bag

|

Main products:

Tetramethylthiuram Monosulfide

/2-Mercaptobenzimidazole

/2-Mercaptobenzimidazole Zinc Salt

/Zinc(Ii) Dibutyldithiocarbamate

/Zinc Bis(Diethyldithiocarbamate)

/Ziram

/Zinc Dibenzyldithiocarbamate

/Zinc N-Ethyl-N-Phenyldithiocarbamate

/Zinc Diisobutyldithiocarbamate

/Ethyl Tellurac

/Sodium Dibutyldithiocarbamate

/Sodium Dibenzyldithiocarbamate

/Dipentamethylenethiuram Hexasulfide

/Thiram

/Tetrabutylthiuram Disulfide

/Disulfiram

/Tetraisobutylthiuram Disulfide

/Diisobutyl Thiuram Monosulfide

/Tetrabenzylthiuram Disulfide

/Zinc 2-Mercaptobenzothiazole

/2-Mercaptobenzothiazole

/2,2'-Dithiobisbenzothiazole

CAS:97-77-8

Molecular Formula:C10H20N2S4

Alias

More Information

Tillram; Tetraethylthiuram Disulfide; Tiuram; TETD; Ttd; Tts; Tts X; Tuads, Ethyl; 1,1’-Dithiobis(N,N-Diethylthio-Formamid; Diethylcarbamothioic Dithioperoxyanhydride; Tetraethylthioperoxydicarbonic Diamide ([[(C2H5)2N]C(S)]2S2); 1,1',1'',1'''-[Disulfanediylbis(Carbonothioylnitrilo)]Tetraethane; 1-(Diethylthiocarbamoyldisulfanyl)-N,N-Diethyl-Methanethioamide

Brief Introduction

Tetraethyl thiuram disulfide belongs to thiuram rubber vulcanization accelerator. This kind of accelerator has fast scorch and vulcanization speed, and belongs to overspeed vulcanization accelerator; Although the vulcanization flatness is small, vulcanized rubber with high tensile strength, tensile strength and hardness can be obtained. Therefore, it can be used as a vulcanizing accelerator of diene rubber or sulfur free vulcanizing agent, and also as a vulcanizing accelerator of low unsaturated rubber.

CNY 60 Million

106560m²

100-500 People

Manufacturing

Manufacturing

| Product Photo | Specification | Grade | Max Capacity | Certificates | Package | |

|---|---|---|---|---|---|---|

|

|

||||||

| Tech Grade | - |

|

25kg /

Paper Bag

|

Main products:

Disulfiram

/2-Mercaptobenzimidazole

/2-Mercaptobenzimidazole Zinc Salt

/Zinc(Ii) Dibutyldithiocarbamate

/Zinc Bis(Diethyldithiocarbamate)

/Ziram

/Zinc Dibenzyldithiocarbamate

/Zinc N-Ethyl-N-Phenyldithiocarbamate

/Zinc Diisobutyldithiocarbamate

/Ethyl Tellurac

/Sodium Dibutyldithiocarbamate

/Sodium Dibenzyldithiocarbamate

/Dipentamethylenethiuram Hexasulfide

/Tetramethylthiuram Monosulfide

/Thiram

/Tetrabutylthiuram Disulfide

/Tetraisobutylthiuram Disulfide

/Diisobutyl Thiuram Monosulfide

/Tetrabenzylthiuram Disulfide

/Zinc 2-Mercaptobenzothiazole

/2-Mercaptobenzothiazole

/2,2'-Dithiobisbenzothiazole

CAS:79-21-0

Molecular Formula:C2H4O3

Alias

More Information

Ethaneperoxoic Acid; Peracetic ACID; Estosteril; Acetic Peroxide; Paracetic acid; Peroxoacetic Acid; Monoperacetic Acid; _|_; перокси

Brief Introduction

Peracetic acid is a member of the organic peroxy acid family. It is a colorless liquid with the typical smell of acetic acid. Peracetic acid is a strong oxidant, highly corrosive and explodes above 110 ° C. Peracetic acid can be prepared by the reaction of acetic acid or acetic anhydride with hydrogen peroxide catalyzed by sulfuric acid. Peracetic acid is used as a disinfectant.

CNY 10 Million

71262m²

100-500 People

Manufacturing

Manufacturing

| Product Photo | Specification | Grade | Max Capacity | Certificates | Package | |

|---|---|---|---|---|---|---|

|

|

||||||

| Tech Grade | - | - |

200kg /

Plastic Drum

|

Main products:

Peroxyacetic Acid

/Propylene Carbonate

/Ethylene Carbonate

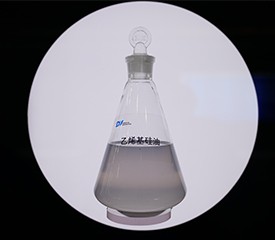

CAS:26710-23-6

Molecular Formula:C6H16OSi2

Alias

More Information

Vinyl Silicone oil; Polyvinyl Methyl Siloxane Fluid; Amorolfine Hydrochloride; Vinylterminatedethylene-Dimethylsiloxanecopolymer

Brief Introduction

Vinyl silicone oil mainly includes vinyl terminated polydimethylsiloxane (VI PDMS) and vinyl terminated polymethylvinyl siloxane (VI PMVs). Products with different viscosity and vinyl content can be provided as required. Vinyl silicone oil can be divided into: terminal vinyl silicone oil and high vinyl silicone oil. It is the main raw material of addition liquid silicone rubber and silicone gel. Modifier of rubber compound / plastic additive / reinforcing material, etc.

CNY 1200 Million

266400m²

500-1000 People

Manufacturing

Manufacturing

| Product Photo | Specification | Grade | Max Capacity | Certificates | Package | |

|---|---|---|---|---|---|---|

|

|

||||||

| Tech Grade | - | - |

200kg /

Iron Drum

|

Main products:

Vinyl Silicone Fluid

/Trimethoxychlorosilanedisc

/Methyltrichlorosilane

/Dichlorodimethylsilane

/Octamethylcyclotetrasiloxane

/Dimethicone

Inquiry (

10

/ 10

)

Clear All

Sign In

Error!