Polyvinyl Alcohol

Polyvinyl Alcohol / CAS : 9002-89-5

| Appearance | White powder, flake or flocculent solid | UN | 0 |

| HS | 39053000 | DG Class | 0 |

| Synonyms | Poly(Vinyl Alcohol); PVA; Poly(1-Hydroxyethylene); PVOH (Polyvinyl Alcohol); P.V.A | ||

- Email: jim.yu@mail.chemball.com

- Whatsapp: 0086-18334372322

- Tel: 0086-571-8627 3270

latest price

-

Non Fibre Grade 24-88

-

Fiber Grade W2

-

Fibre Grade 80S

-

Non Fibre Grade 17-99

-

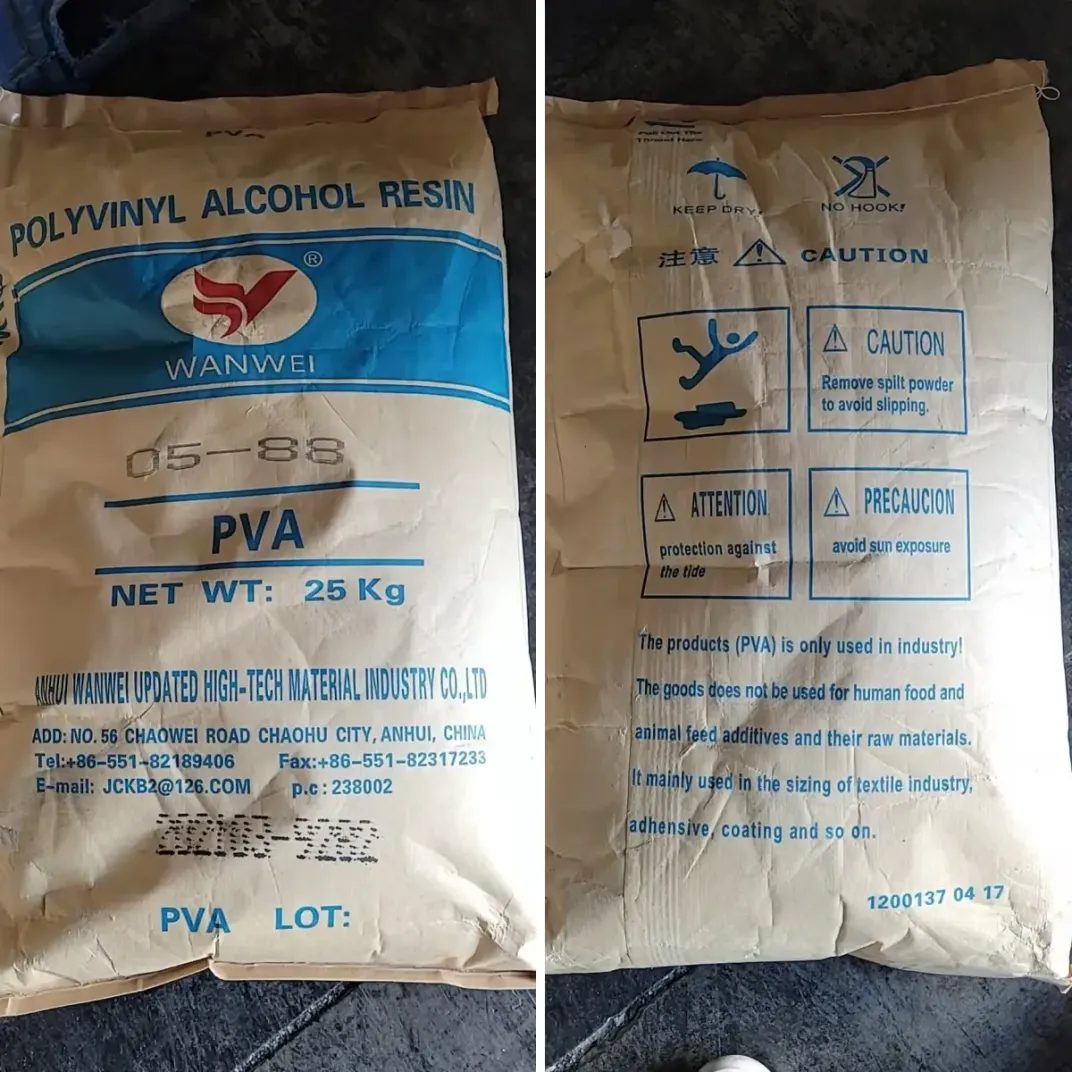

Non Fibre Grade 05-88

-

Non Fibre Grade 26-88

-

Non Fibre Grade 04-88

-

Non Fibre Grade 20-88

-

Non Fibre Grade 20-88A

-

Non Fibre Grade 26-99

-

Non Fibre Grade 30-99

-

Non Fibre Grade 04-99

-

Non Fibre Grade 05-99

-

Non Fibre Grade 15-99

-

Non Fibre Grade 20-99

-

Non fibre 17-88

-

28-88

Overview

Benefits

Polyvinyl alcohol (PVA) series products have complete independent intellectual property technology, three process routes, and a complete variety.

The world's largest PVA production base.

The annual production capacity of PVA synthesized from calcium carbide acetylene reaches 200000 tons, and more than 40 products with different degrees of polymerization and alcoholysis can be produced in bulk.

Affiliated with Wanwei Group, has completed the world's first set of biomass VAC and PVA production equipment using sugarcane and other biomass resources.

The annual production capacity of biomass PVA is 50000 tons, and the product is highly friendly to human health and the environment.

Specification

Not FIBER Grade WANWEIPVASPECIFICATION(Low alkali)

Item | Corresponding National Standard | Degree of Alcoholysis / % (Mol/mol) | Viscosity / mpa.s | Volatile / % ≤ | Sodium Acetate / % ≤ | Ash / % ≤ | PH |

03-88(L) | / | 85.0~90.0 | 2.5~3.5 | 7 | 1.8 | 0.7 | 5~7 |

03-97(L) | / | 95.0~99.0 | 3.0~4.0 | 7 | 1.8 | 0.7 | 5~7 |

04-88(L) | / | 85.0~90.0 | 3.5~4.5 | 7 | 1.8 | 0.7 | 5~7 |

04-99(L) | / | 98.0~99.80 | 3.5~4.5 | 7 | 1.8 | 0.7 | 5~7 |

05-88(L) | 088-05 | 85.0~90.0 | 4.5~6.5 | 7 | 1.8 | 0.7 | 5~7 |

05-99(L) | 098-05 | 98.0~99.8 | 4.5~7.0 | 7 | 1.8 | 0.7 | 5~7 |

08-88(L) | / | 85.0~90.0 | 6.5~8.0 | 7 | 1.8 | 0.7 | 5~7 |

08-99(L) | / | 98.0~99.8 | 7.0~9.0 | 7 | 1.8 | 0.7 | 5~7 |

10-88(L) | 088-08 | 85.0~90.0 | 8.0~11.0 | 7 | 1.8 | 0.7 | 5~7 |

10-99(L) | 098-08 | 98.0~99.8 | 8.0~12.0 | 7 | 1.8 | 0.7 | 5~7 |

13-88(L) | / | 86.0~90.0 | 11.0~14.0 | 7 | 1.8 | 0.7 | 5~7 |

14-92(L) | / | 90.0~94.0 | 13.0~17.0 | 7 | 1.8 | 0.7 | 5~7 |

15-99(L) | / | 98.0-99.8 | 13.0~18.0 | 7 | 1.8 | 0.7 | 5~7 |

17-88(L) | 088-20 | 85.0~90.0 | 20.0~28.0 | 7 | 1.8 | 0.7 | 5~7 |

17-92(L) | 092-20 | 90.0~94.0 | 20.0~28.0 | 7 | 1.8 | 0.7 | 5~7 |

17-98(L) | / | 97.0~99.0 | 24.0~32.0 | 7 | 1.8 | 0.7 | 5~7 |

17-99(L) | 100-27 | 99.0~100.0 | 22.0~32.0 | 7 | 1.8 | 0.5 | 5~7 |

20-88(L) | 088-35 | 85.0~90.0 | 28.0~40.0 | 7 | 1.8 | 0.5 | 5~7 |

20-92(L) | 092-35 | 90.0~94.0 | 29.0~40.0 | 7 | 1.8 | 0.7 | 5~7 |

20-99(L) | 100-35 | 99.0~100.0 | 35.0~48.0 | 7 | 1.8 | 0.7 | 5~7 |

24-88(L) | 088-50 | 85.0~90.0 | 43.0~58.0 | 7 | 1.8 | 0.7 | 5~7 |

24-99(L) | 100-72 | 99.0~100.0 | 65.0~85.0 | 7 | 2.5 | 1 | 5~7 |

26-99(L) | 100-86 | 99.0~100.0 | 85.0~100.0 | 7 | 1.8 | 0.7 | 5~7 |

Not FIBER Grade WANWEIPVASPECIFICATION(High alkali)

Item | Corresponding National Standard | Degree of Alcoholysis / % (Mol/mol) | Average degree of polymerization (Mol/mol) | Viscosity / mpa.s | Volatile / % ≤ | Sodium Acetate / % ≤ | Ash / % ≤ | PH |

17-99(H) | 100-27H | 99.0~100.0 | 1600~1800 | 20.0~26.0 | 8 | 2.8 | 2.8 | 7~10 |

19-99(H) | 100-31H | 99.0~100.0 | 1800~2000 | 26.0~34.0 | 8 | 1.3 | 2.8 | 7~10 |

20-99(H) | 100-37H | 99.0~100.0 | 2000~2300 | 34.0~42.0 | 8 | 1.3 | 2.8 | 7~10 |

23-99(H) | 100-50H | 99.0~100.0 | 2300~2600 | 42.0~55.0 | 6.5 | 1.3 | 2.5 | 7~10 |

22-99(H) | Guangxi Wanwei | 99.0~100.0 | 2300~2600 | 42.0~55.0 | 8 | 1.3 | 2.8 | 7~10 |

24-99(H) | 100-60H | 99.0~100.0 | 2600~2900 | 55.0~65.0 | 8 | 1.3 | 2.8 | 7~10 |

FIBER Grade WANWEIPVASPECIFICATION

Item | Degree of Alcoholysis / % (Mol/mol) | Average degree of polymerization (Mol/mol) | Volatile / % ≤ | Sodium Acetate / % ≤ | Ash / % ≤ | Purity / % ≥ | Transparency / % ≥ | Sodium hydroxide / % ≤ |

Conventional water-soluble material 17-99 (L) | 99.5~100.0 | 1700~1800 | 5 | 2 | 0.8 | 93 | 95 | 0.1 |

High strength material 17-99 (L) | 99.8~100.0 | 1750~1900 | 5 | 2.5 | 1 | 92.5 | / | / |

Uses

Adhesive: PVA can be used as an adhesive for many different materials, such as paper, textiles, wood, plastics, etc. It has high viscosity and good durability, making it widely used in industrial applications such as paper and fiberboard manufacturing.

Coatings and adhesives: PVA can also be used to manufacture various coatings and adhesives, such as wall coatings, wood coatings, adhesives, etc. In these applications, PVA can provide good adhesion and water resistance.

Packaging material: Due to its excellent water resistance and high transparency, PVA is also used as a packaging material, such as food packaging bags and cosmetics packaging.

Medical use: PVA can also be used to manufacture medical supplies, such as eye drops, artificial blood vessels, wound dressings, etc. These products, due to their excellent biocompatibility and biodegradability, can effectively help treat diseases and wounds.

Cellulose fiber processing: PVA can also be used for cellulose fiber processing, such as manufacturing cellulose pads and artificial plush toys.

Picture

Properties

Summary

Attribute classification

Organic Chemical Materials > Alcohols, Phenols and Ethers